Documentation

Sample Gcode

Hardware Example

News Archive

Download

Buy Now

Payment, Shipping & Returns

Privacy Policy

Videos

Leadscrew Cover

PCB Cutout

Pinion Gear

G64 Path Blending

Fusion 360 Clamps

Fusion 360 Threads

Sherline

Shapeoko 2

Gecko G540

Sherline 3D Printer

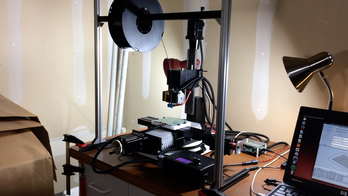

Sherline 3D printer with rt-stepper 4-axis motor drive example

Sherline 2000 mill converted to 3D printer

Sherline Products is not in the business of manufacturing 3D printers, however Sherline does offer parts for building a 3D printer. There are many good 3D printers available on the market today, but I did not want to dedicate any more desk space to a separate machine. Since I already have a Sherline 2000 mill I decided to convert the mill to a 3D printer. Actually I have made two conversion (1) the Sherline 2000 mill was converted to a Sherline 5400 mill column and 14 inch base, (2) I replaced the Sherline spindle with the Sherline 3D Print-Head Bracket (89505) and Sherline Print-Head Saddle Mounting Plate (89507).

Sherline only sells the Print-Head Bracket and Print-Head Saddle Mounting Plate. The rest of the 3d printer parts are available online which make this a DIY only project.

USB Solution

There are four stepper motors on the Sherline 3D printer - X,Y,Z and A axis. The only difference between a normal XYZ mill is the A axis. The A axis is used to drive the print head filament stepper motor. Since all the stepper motors are bipolar (4 wire) I used the rt-stepper 4-axis motor drive board to drive all four stepper motors. The 4-axis motor drive plugs into a notebook via USB cable.

Software

The software that drives the rt-stepper 4-axis motor drive is pymini. Pymini will execute the gcode program generated by Repetier-Host with slic3r slicer. Repetier will generate all gcode in metric. My Sherline 2000 is a inch machine, but I have the pymini stepstick_2000_3d.ini file setup to run in mm.

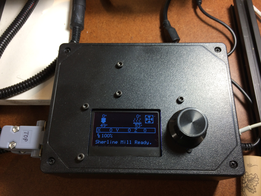

A temperature controller is used to control the temperature of the print head and heated bed only. The temperature controller operates independent of pymini. The controller was built using an Arduino mega 2560 board, ramps 1.4 board and mini full graphic LCD display.

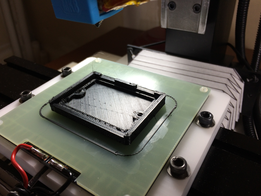

Hardware in Motion

All the Sherline 3D printer electronics is 24v, so a single 24v power supply drives everything. The extruder is a MK8 print head. On top of the 100x100mm heated bed is a polypropylene glass fiber build plate. Here is a Sherline 3D printer demo running at a conservative 12 mm/sec for X,Y,Z motors and 20 mm/sec for the A motor. The ABS part being printed is the bottom half of a rt-stepper dongle case.